BIOMERE - biodegradable waxes

Avoid microplastics!

Microplastics, plastic waste and environmental pollution in general are among the major challenges of today. We are making an active contribution to curbing microplastics and addressing this issue by developing and marketing of biodegradable waxes - BIOMERE.

Environmental and nature awareness have long since ceased to be marketing topics and have great social relevance. People are living more sustainably, companies are producing more sustainably and politics are creating sustainable regulations. With BIOMERE we are continuing to play our pioneering role in the field of wax additives and are now introducing BIOMERE as an alternative to conventional polymers.

Major benefits

- BIOMERE® - biodegradable waxes

- Avoid the formation of microplastics

- Certified biodegradability

- Up to 100% bio-based products

- Same performance and properties as non-degradable waxes

- Biodegradability tailored to the final product

- Delivery forms tailored to applications

Biodegradable waxes

- Free of microplastics: Unlike conventional polymeric additives no microplastics emerge from BIOMERE®.

- Biodegradability: BIOMERE®degrade biologically as soon as they are exposed to the aquatic environment.

Certified biodegradability

The biodegradability of all waxes of the BIOMERE® - series is certified.

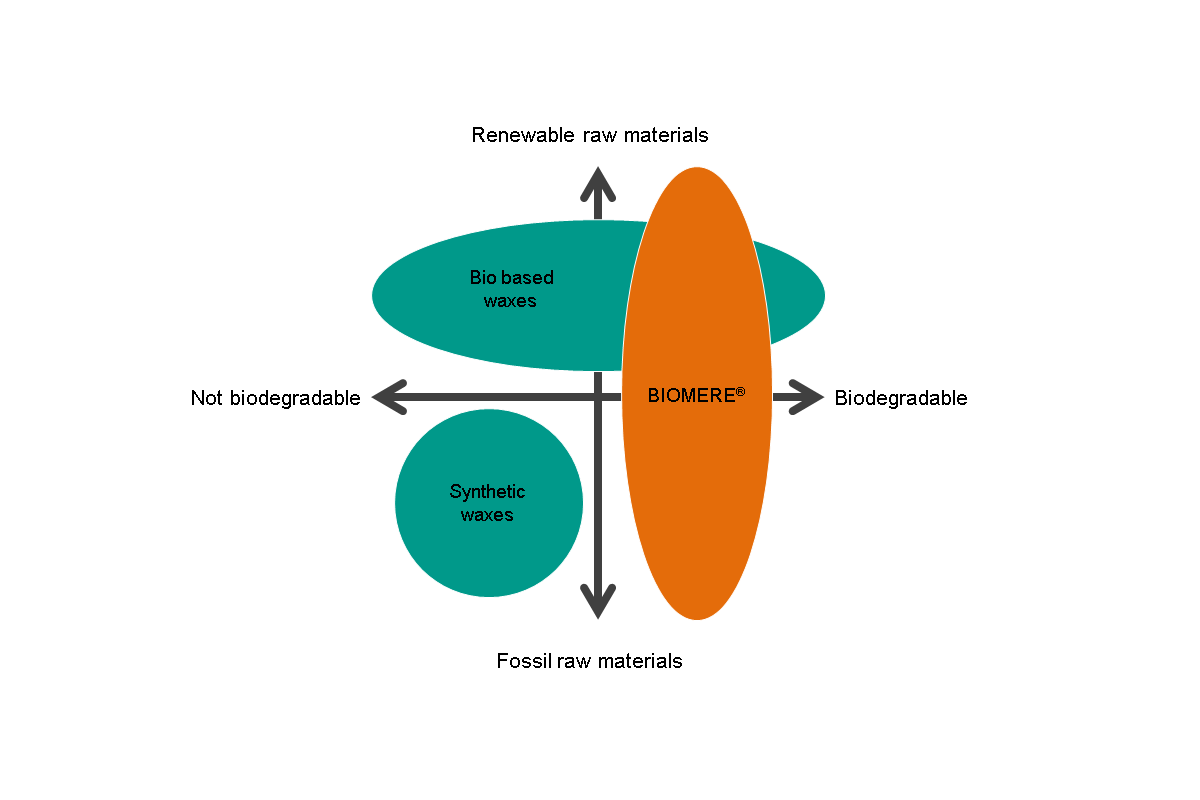

Up to 100 % bio based waxes

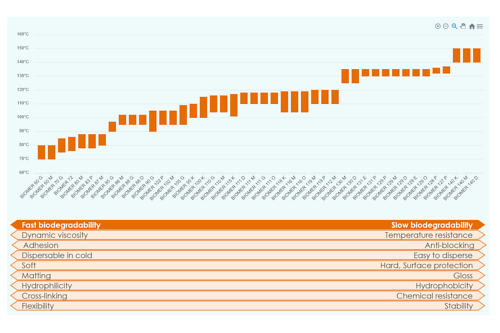

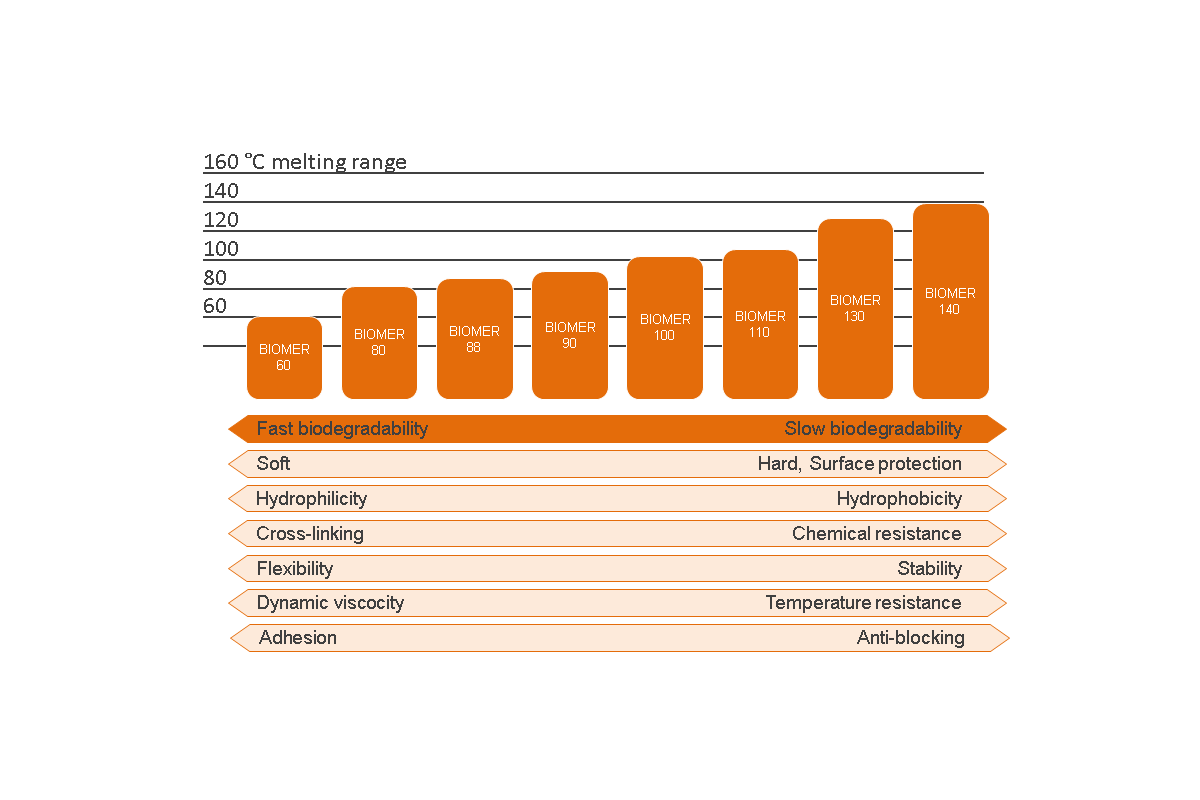

All waxes of the BIOMERE series are biodegradable. Biodegradability does not necessarily require bio based products. Also fossil based products can be biologically degraded. The graph above illustrates this. As "the wax company" DEUREX is in the position to offer the complete portfolio of waxes. Biodegradable waxes, synthetic waxes, waxes of natural origin and waxes of fossil origin.

Same performance as non-degradable waxes

The waxes of the BIOMERE series can cover the same benefits as non-degrabable waxes. They are used to modify surface properties and to act as processing agents.

Surface properties that can be improved by using waxes are: Higher gloss or matting effects. A nice smoothness and pleasant haptical effects. Resistance against scratch, abrasion and weather conditions.

Waxes as processing agents can adjust a lot of parameters. Depending on the application, waxes work as internal and external lubricants. Waxes can adjust viscosity, pressure, torque. Waxes can work as dispersing agents, release agents and retarding agents.

Waxes are true all-rounders.

Biodegradability adapted to specific final product

Main pathways of microplastics into the environment

- Down-the-Drain (DTD): Through bio solids, sewage sludge into the environment

- Municipal Solid Waste (MSW): e.g. through landfills and waste incineration

- Direct release: Improper disposal and the use of everyday products

Types of microplastics

Primary microplastics, Type A

- Microplastics, which are deliberately industrially produced and deliberately used as an additive in numerous products in everyday life

- Particles that are added to household care and cleaning products or cosmetics

- Microplastics are also used to coat plants and fertilizer products or citrus fruits

- Paints, varnishes and plastic granulates that are used as raw material for the industrial production of plastic parts and films

According to estimates from the European Commission's final report, more than 50,000 tonnes of microplastics are released unhindered into the environment every year in the EU alone (DG-Environment).

Examples for primary microplastics, Type A:

- Agriculture / Plastics in fertilizer, pesticides and seed coatings

- Cosmetics / Exfoliating, cleansing, make-up

- Paints and varnishes / Film-forming, surface improvements

- Detergents and cleaning agents / Surface cleaning products, fabrics softeners, dishwashing products

- Care products and polishes / for shoes, furniture, cars, floors,…

- Fruit coatings

- Pharmaceuticals / Coated for controlled release and protection of substances

- Food supplements / Coated for controlled release

- Oil and gas industry / Additives for drilling

- Adhesives / Spacers

- Blasting, high pressure cleaning

- 3D -printing

Primary microplastics, Type B

- Released micro particles that are created during the use phase of a product

- Synthetic fibres released during the washing of garments

- Abrasion from tyres, bitumen, brakes or shoe soles

- Drifts from sports fields and playgrounds

- A multitude of other plastic sources such as house facades, cables or road markings

Type B microplastics are a major contributor to the microplastics problem. According to EU Commission estimates every year up to 280,600 tonnes of microplastics are released into the environment in this way (ECHA, 2019)).

Examples for primary microplastics, Type B:

- Road traffic / Abrasion of tires, brakes and bitumen

- Waste disposal / Private households and supermarkets, non-degradable plastics in compost

- Textiles / Release of plastic fibres, manufacturing, prints on textiles

- Construction / Reinforced concrete

- Fascades and paintwork / Binders

- Fishing / Ghost nets

- Packaging / Uncontrolled release via weather into environment

- Paper production / Paper often contains plastics

Secondary microplastics

- Plastics that are formed by the degradation and decomposition of larger plastic pieces into smaller and smaller plastic fragments

- Process is accelerated as soon as microplastics are exposed to the aquatic environment

- The plastic particles are broken down by photodegradation and other weathering processes

- Mostly from improperly disposed waste, such as discarded plastic bags